Are you tired of wearing socks that wear out quickly and harm the environment? Well, fret no more because sustainable solutions have arrived! In this article, we will explore the exciting eco-friendly advances in sock manufacturing. From using recycled materials to implementing sustainable practices, sock production has undergone significant transformations to minimize its environmental impact. So get ready to step into a world of greener, more durable, and stylish socks!

This image is property of images.pexels.com.

Recycled Materials

In recent years, there has been a growing trend in the fashion industry towards using recycled materials, and this includes the production of socks. Recycled polyester yarn, for example, is obtained from post-consumer plastic bottles and other plastic waste. By repurposing these materials, manufacturers can reduce their dependence on virgin polyester, which requires significant amounts of energy and resources to produce. Recycled cotton is another popular choice for sustainable sock manufacturing. This material is made by collecting textile scraps, cutting them into small pieces, and then blending them with virgin cotton to create a new yarn. By using recycled cotton, companies can help reduce the amount of waste that ends up in landfills. Recycled nylon is another eco-friendly option for sock production. It is derived from discarded fishing nets and other nylon waste, which would otherwise contribute to environmental pollution. By utilizing recycled materials in the manufacturing process, companies can significantly reduce their environmental impact and contribute to a more sustainable future.

Organic Fibers

In addition to using recycled materials, many sock manufacturers are now turning to organic fibers in their production processes. Organic cotton, for example, is grown without the use of synthetic chemicals such as pesticides and fertilizers. This reduces the risks of water and soil pollution, as well as potential health hazards for farmers and workers. Bamboo fiber is another organic option for sock production. Bamboo plants are known for their fast growth and the ability to thrive without the need for pesticides or herbicides. The fibers extracted from bamboo are highly versatile and can be used to make soft and breathable socks. Hemp is also gaining popularity as an organic material for socks. Hemp plants require minimal amounts of water and grow quickly, making it a sustainable choice for textile production. By opting for organic fibers, manufacturers can ensure that their products are free from harmful chemicals and contribute to a healthier planet.

This image is property of images.pexels.com.

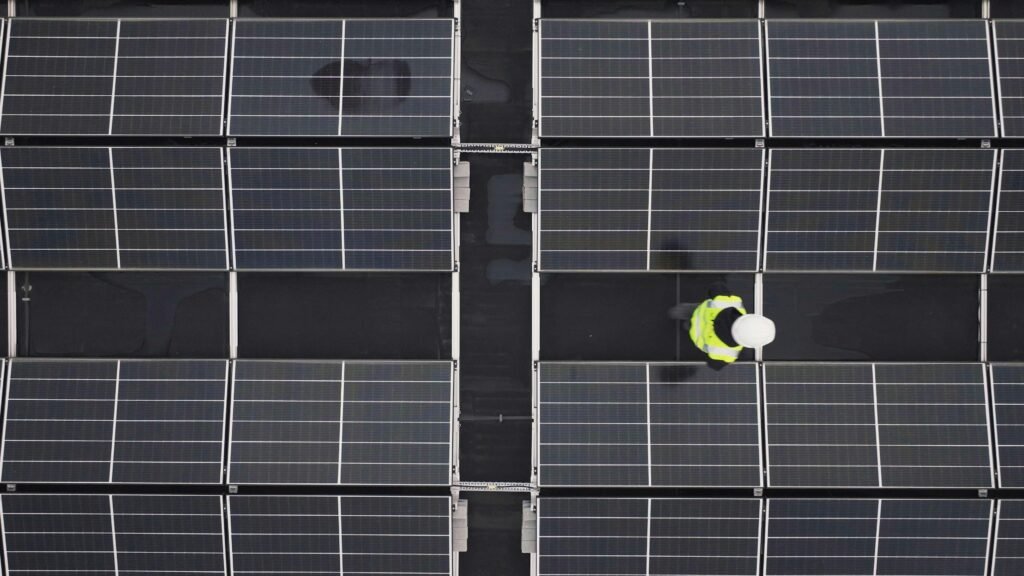

Renewable Energy

Another significant advancement in sock manufacturing is the use of renewable energy sources to power production facilities. Solar power, for instance, harnesses energy from the sun through the use of solar panels. By utilizing this clean and abundant energy source, companies can significantly reduce their carbon emissions and environmental footprint. Similarly, wind power uses turbines to convert wind energy into electricity. This renewable energy source is currently being harnessed by many manufacturers to power their production processes. Hydropower is another sustainable option, utilizing the energy of moving water to generate power. By relying on renewable energy sources, sock manufacturers can lessen their reliance on fossil fuels and contribute to the transition towards a greener economy.

Water Conservation

Water is a precious resource, and its conservation is of utmost importance in sustainable sock manufacturing. To minimize water usage, many manufacturers are implementing water recycling systems. These systems capture and treat wastewater from production processes, allowing it to be reused in subsequent manufacturing cycles. Additionally, waterless dyeing techniques have been developed to eliminate the need for large amounts of water traditionally required in the dyeing process. Instead of using water as a medium for dye application, these techniques utilize innovative methods such as air or steam to bind the color to the fabric. Furthermore, manufacturers are continually striving to reduce overall water consumption by optimizing their processes and exploring new technologies. By emphasizing water conservation, sock manufacturers can minimize their environmental impact and contribute to preserving this invaluable resource.

This image is property of images.pexels.com.

Chemical-Free Processes

To reduce the use of harmful chemicals in sock manufacturing, various chemical-free processes have been introduced. Natural dyeing methods, for instance, utilize plant-based dyes to color the socks. These dyes are derived from natural sources such as flowers, leaves, and roots, ensuring that no harsh chemicals are released into the environment during the dyeing process. Enzyme treatments are another eco-friendly option, using natural enzymes to enhance the softness and durability of the socks. These enzymes are biodegradable and pose no harm to the environment. Low-impact pigments are also gaining popularity, as they are free from heavy metals and other harmful substances. By adopting chemical-free processes, sock manufacturers can offer products that are safer for both consumers and the planet.

Zero-Waste Manufacturing

Efforts towards zero-waste manufacturing have become a priority in the sock industry. By implementing efficient pattern cutting techniques, manufacturers can optimize fabric utilization and minimize waste. This means that more socks can be produced from the same amount of fabric, reducing the need for additional resources. Another strategy is upcycling production waste. Rather than discarding leftover materials, manufacturers find creative ways to repurpose them into new products or integrate them into the manufacturing process. This not only reduces waste but also adds value to materials that would have otherwise been considered unusable. Closed-loop manufacturing is another approach to zero-waste production. This concept involves creating a closed system where materials are continuously recycled and reused, leaving no waste behind. By embracing zero-waste manufacturing practices, sock manufacturers can demonstrate their commitment to sustainability and inspire others to follow suit.

Carbon Footprint Reduction

Reducing carbon emissions is a critical aspect of sustainable sock manufacturing. Companies are actively seeking ways to optimize transportation by reducing the distance traveled and consolidating shipments. By adopting energy-efficient machinery, manufacturers can minimize energy consumption and decrease their carbon emissions. Upgrading to more sustainable energy sources, such as solar or wind power, can also contribute to a significant reduction in a company’s carbon footprint. Some manufacturers are also engaging in carbon offset initiatives, where they invest in projects that reduce greenhouse gas emissions or promote renewable energy. These initiatives help offset any unavoidable emissions and contribute to the overall goal of a more sustainable and carbon-neutral sock manufacturing industry.

Fair Trade Practices

Ensuring fair wages and safe working conditions for all workers involved in sock production is an essential aspect of sustainability. Many companies now prioritize fair trade practices by working with suppliers who provide fair wages, safe working conditions, and other social benefits for their employees. This ensures that workers have access to a living wage and are not exploited in the manufacturing process. Supporting local communities is another important element of fair trade practices. By sourcing materials locally and collaborating with local artisans and businesses, sock manufacturers can contribute to the economic development of the communities in which they operate. By advocating for fair trade practices, sock manufacturers can make a positive impact on the lives of workers and promote social justice.

Biodegradable Packaging

Sustainable sock manufacturing goes beyond the production process and extends to packaging as well. Biodegradable packaging materials, such as compostable sock wraps, help reduce waste and minimize the environmental impact of packaging. These wraps break down naturally over time, returning to the earth without causing harm. Similarly, recyclable paper tags are favored over plastic tags, as they can be easily recycled and reused. Plant-based sock bags are another eco-friendly option. Made from renewable resources, these bags decompose safely in the environment without leaving any harmful residues. By opting for biodegradable packaging materials, sock manufacturers can ensure that their commitment to sustainability extends to every aspect of their product, from production to disposal.

Longevity and Repairability

An important element of sustainable sock manufacturing is the focus on longevity and repairability. Socks are designed with reinforced toes and heels for added durability, ensuring that they last longer and withstand regular wear and tear. Additionally, some manufacturers provide spare yarn with their socks, enabling customers to repair any minor damages themselves. By offering repair services, manufacturers can extend the lifespan of their products and reduce the need for replacement. These practices encourage consumers to adopt a more sustainable approach to their sock consumption by valuing longevity and repairability over disposability. By prioritizing durability and repairability, sock manufacturers can contribute to a circular economy where products are used for longer periods and waste is minimized.

In conclusion, sustainable sock manufacturing has made significant progress in recent years. By using recycled materials, utilizing organic fibers, relying on renewable energy sources, conserving water, adopting chemical-free processes, embracing zero-waste manufacturing, reducing carbon footprints, practicing fair trade, using biodegradable packaging, and prioritizing longevity and repairability, companies can produce socks that are both fashionable and eco-friendly. These advancements in sock production not only contribute to a healthier planet but also resonate with conscious consumers who seek to support sustainable and ethical practices. By making sustainable choices in sock manufacturing, companies can be part of the solution in creating a more sustainable and environmentally friendly future.